詳細介紹

Metal software is used for automatic steel and alloys structure quality control by techniques of metallographic analysis according to international standards (ASTM, ISO, DIN, SEP, JIS).

The software can be used at industrial laboratories, departments of scientific research institutes, testing laboratories and other institutions performing routine factory, qualification, certification and other tests of metals and alloys structure by standard metallographic methods.

The software applying allows expediting routine procedures of materials metallographic analysis and technological processes of metallurgical treatment as well as increasing results of control accuracy and reliability.

During analyzing by any available standard the analyzer simultaneously performs measurements and calculations by methodologically similar methods enabling to view and print out the report with analysis results for each standard.

Main software features:

- Images input via digital cameras (including 8, 10, 12, 16-bit), scanner and opening images from files;

- Automatic quantitative evaluation of microstructures by routines included in the software;

- Recalculating analysis results from one standard to other methodologically similar standards;

- Automatic forming reports with analysis results in accordance with standard selected;

- Printing out reports;

- Saving images and analysis results in a single document or in databases built in VideoTesT – Metal software.

Metal software works as a part of image analyzer for metals and alloys quality control. It should be supplied with the following equipment:

- Inverted or upright microscope for work in reflected light;

- Motorized stage to analyze large number of fields of view in accordance with standards requirements;

- Digital color or black-and-white camera;

- Personal computer with peripheral devices;

- Printer enabling photo printing.

Metal - software is for automatic sections of metals, steels, alloys and cast-iron structure evaluation in accordance with international metallography standards (ASTM, ISO, DIN, SEP, JIS).

VideoTesT – Metal software basis consists of routines – sequences of image processing operations performed in fully automatic mode or with minimal operator participation.

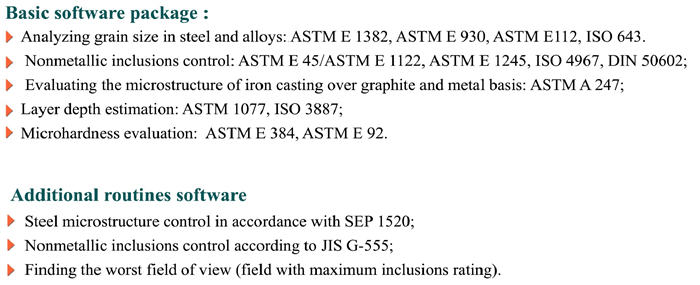

The basic software package includes routines enabling work on the following directions and standards:

- Analyzing grain size in steel and alloys: ASTM E 1382, ASTM E 930, ASTM E112, ISO 643.

- Nonmetallic inclusions control: ASTM E 45/ASTM E 1122, ASTM E 1245, ISO 4967, DIN 50602;

- Evaluating the microstructure of iron casting over graphite and metal basis: ASTM A 247;

- Layer depth estimation: ASTM 1077, ISO 3887

- Microhardness evaluation: ASTM E 384, ASTM E 92.

Routines included in basic package are built in the software and cannot be excluded on customer’s demand.

Following additional routines can be included into software on customer’s demand on commercial basis:

- Steel microstructure control in accordance with SEP 1520

- Nonmetallic inclusions control according to JIS G-555

- Finding the worst field of view (field with maximum inclusions rating).

On customer’s demand specialists of VideoTesT company can develop and include in the software new additional routines corresponding to required normative documents.

Main software features:

- Images input via digital cameras (including 8, 10, 12, 16-bit), scanner and opening images from files;

- Automatic quantitative evaluation of microstructures by routines included in the software;

- Recalculating analysis results from one standard to other methodologically similar standards;

- Automatic reports with analysis results forming in accordance with standard selected;

- Printing out reports;

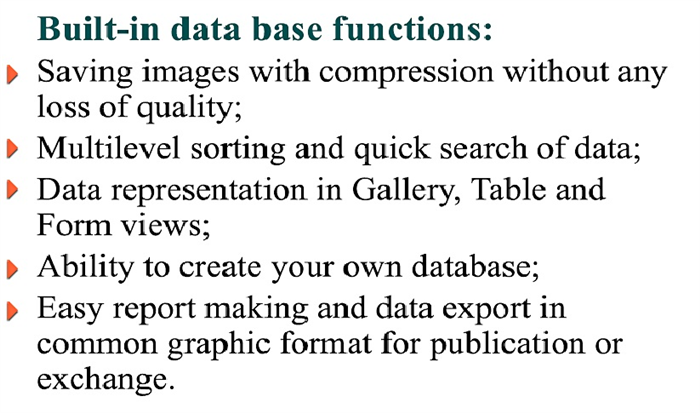

- Saving images and analysis results in a single document or in databases built in VideoTesT – Metal software.

Additional software capabilities:

- Automatic “comparison with reference diagrams” technique performing;

- Evaluating whole analyzed area;

- Adding graphics, texts and calibration bar to the images;

- Performing manual measurements in “free mode”;

- Customizing report templates to print out results in a form approved in the organization.

DOWNLOAD: